From Pro helpThe following table lists all system parameters available for use in drawings, classified according to functionality.

PARAMETER NAME DEFINITION

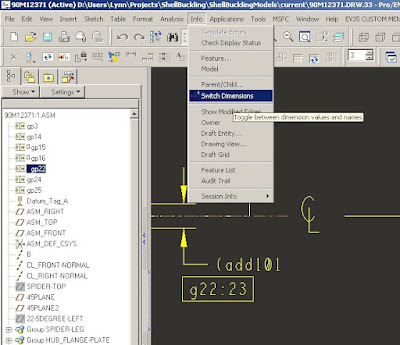

&d# Displays a dimension in a

drawing note, where # is the dimension ID.

&ad# Displays an associative

dimension in a drawing note, where # is the dimension ID.

&rd# Displays a reference dimension

in a drawing note, where # is the dimension ID.

&p# Displays an instance number of

a pattern in a drawing note, where # is the pattern ID.

&g# Displays a gtol in a drawing

note, where # is the gtol ID.

& Displays a user-defined parameter value in a

drawing note.

&:att_cmp An object parameter that indicates the

parameters of the component to which a note is attached.

&:att_edge An object parameter that indicates the

parameters of the edge to which a note is attached.

&:att_feat An object parameter that indicates the

parameters of the feature to which a note is attached.

&:att_mdl An object parameter that indicates the

parameters of the model to which a note is attached.

&:att_pipe_bend An object parameter that indicates

the parameters of the pipe bend to which a note is attached.

&:att_spool An object parameter that indicates the

parameters of the spool to which a note is attached.

&:EID_ An object parameter that

references edges.

&:FID_ An object parameter that includes

a feature parameter in a note by ID.

&:FID_ An object parameter that includes

a feature parameter in a note by name.

&:SID_ An object parameter that

references surfaces.

&angular_tol_0_0 Specifies the format of angular

tolerance values in a note from one to six decimal places.

¤t_sheet Displays a drawing label indicating the

current sheet number.

&det_scale Displays a drawing label indicating the

scale of a detailed view. You cannot use this parameter in a drawing note.

Pro/ENGINEER creates this parameter with a view and places it in notes

automatically. You can modify its value, but you cannot call it out in another

note.

&dtm_name Displays datum names in a drawing note,

where name is the name of a datum plane. The datum name in the note is

read-only, so you cannot modify it; unlike dimensions, a datum name does not

disappear from the model view if included in a note. Pro/ENGINEER encloses its

name in a rectangle, as if it were a set datum.

&dwg_name Displays a drawing label indicating the

name of the drawing.

&format Displays a drawing label indicating

the format size (for example, A1, A0, A, B, and so forth).

&linear_tol_0_0 Specifies the format of dimensional tolerance

values in a note from one to six decimal places.

&model_name Displays a drawing label indicating the name

of the model used for the drawing.

¶meter:d Adds drawing parameters to a drawing note,

whereparameter is the parameter name and :d refers to the drawing. .

&pdmdb Displays the database of origin of

the model.

&pdmrev Displays the model revision.

&pdmrev:d Displays the revision number of the

model (where :d refers to the drawing).

&pdmrl Displays the release level of the

model.

&scale Displays a drawing label

indicating the scale of the drawing.

&scale_of_view_detailed_bar

&sym() Includes a drawing symbol in a note, where

symbolnameis the name of the symbol.

&todays_date Displays a drawing label indicating the date

on which the note was created in the form dd-mm-yy (for example, 2-Jan-92). You

can edit it as any other nonparametric note, using Text Line or Full Note.

If you include this

symbol in a format table, Pro/ENGINEER evaluates it when it copies the format

into the drawing.

To specify the initial

display of the date in a drawing, use the configuration file option

"todays_date_note_format."

&total_sheets Displays a drawing label indicating the

total number of sheets in the drawing.

&type Displays a drawing label

indicating the drawing model type (for example, part, assembly, etc.).

&view_name Displays a drawing label indicating the

name of the view. You cannot use this parameter in a drawing note. Pro/ENGINEER

creates it with a view and places it in notes automatically. You can modify its

value, but you cannot call it out in another note.

&view_scale Displays a drawing label indicating the

name of a general scaled view. You cannot use this parameter in a drawing note.

Pro/ENGINEER creates it with a view and places it in notes automatically. You

can modify its value, but you cannot call it out in another note.

Pro/REPORT System

Parameters

&asm.mbr.comp.... Retrieves information about the component

from the model data and displays it in the report table.

&asm.mbr.cparam.... Retrieves a given component parameter.

&asm.mbr.cparams.... Lists information pertaining to all component

parameters for the current model.

&asm.mbr.name Displays the name of an assembly

member. To show tie wraps and markers, the region attributes must be set

toCable Info.

&asm.mbr.param.... Displays information about parameters in

an assembly member.

&asm.mbr.type Displays the type (part or assembly) of an

assembly member.

&asm.mbr.User

Defined Lists the specified user-defined

parameter for the respective assembly components. Note that

"&asm.mbr." can be used as a prefix before any

user-defined parameter

in an assembly member.

&dgm....

&fam.... Retrieves family table information

about the model.

&harn.... Shows cable harness parameters for

3-D harness parts and flat harness assemblies.

&lay.... Retrieves layout information about

the model.

&mbr.... Retrieves parameters about a single

component.

&mdl.... Retrieves information about a single

model.

&prs.... Retrieves process-specific report

parameters used to create reports on the entire process sequence.

&rpt.... Displays information about each

record in a repeat region.

&weldasm.... Retrieves welding information about the

model.

&asm.mbr.cblprm.... Lists values for a given cabling

parameters.

&asm.mbr.cblprms.... Lists values for cabling and wire parameters.

&asm.mbr.connprm.... Lists parameters for connector pins in flat

harness assemblies.

&asm.mbr.location... Lists the location callouts in a specified

view or all views of the drawing in session.

&asm.mbr.pipe.... Shows pipeline, pipe segment, and Pro/REPORT

bend information parameters.

&asm.mbr.generic.name…. Lists the generic name information for a

family table instance in a table.

&asm.mbr.topgeneric.name…. Lists the top generic name information for a

family table instance in a table when working with a nested family table.

-->